- Home

- Product

- Two-Component Liquid Meter Mix Dispenser

Product

Two-Component Liquid Meter Mix Dispenser

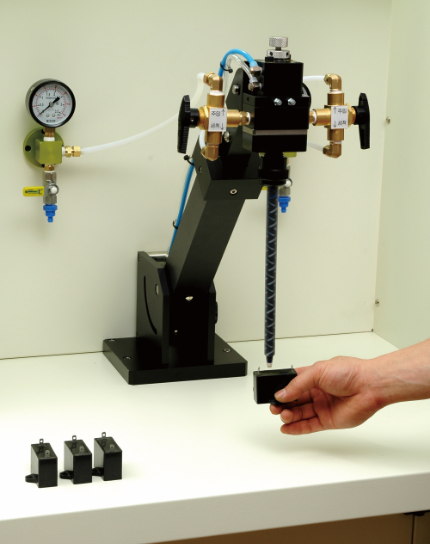

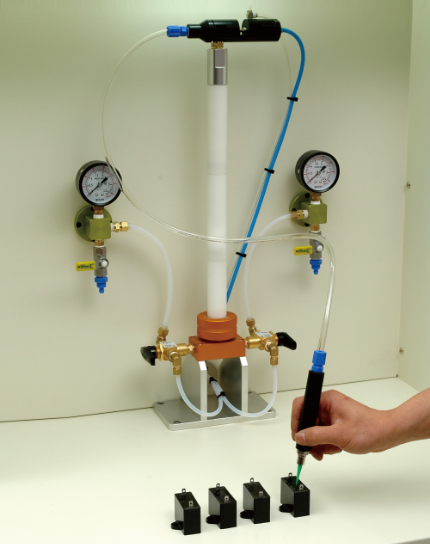

Meter Mix Dispenser Compact PR-2D Ⓡ

No mixing ratio change due to the changes in the viscosity and the pipe resistance

Static mixer method ensures a longer operation period

Maintain the correct mixing ratio with the metering system with two speed controlled geared motors and two gear pumps.

Completely clean the inside of the mixer with two-step automatic cleaning (cleaning agent/air pressure) after daily operation (operated on the control panel)

Standard Specifications

Mixing Rate

Select within 100:100 ~ 100:10 (Fixed – Mixing Rate Type)

Shot Amount

1cc / sec-10cc.sec (Digital Timer Type)

Mixing Accuracy

Shot Accuracy

Viscosity

Auto anti-gel shot

A/B Tank

Cleaner Tank

Mixer

Shot Signal

Control Type

Electricity

Air Pressure

Standard Option

Tank / Line Preheater

Tank Agitator

Tank Vacuum Degassing Device

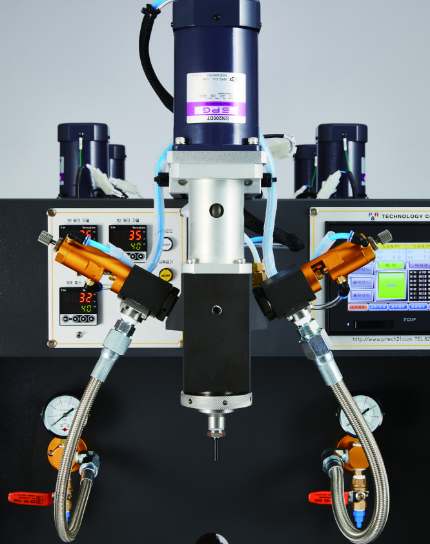

Advantages of the PR-2D Compact TYPE

- Adopted the 4-stage structure (existing 3-stage valve structure) to improve the durability of the fixed-quantity discharge valve compared to competitors and to facilitate easy disassembly during service

- Each of the primary liquid and curing agent pumps are driven by individual motors and an inverter control, and the mixing ratio can be easily controlled

- Used the 3-way automated valve on the vacuum pump in addition to the existing water separator when using the vacuum pump to prevent the backflow of the liquid in the tank or the backflow of oil from the vacuum pump and solve the existing problems

The smallest unit in Korea (for 30L tanks)

- The most compact design available from a Korean manufacturer at Width (800m/m) x depth (870m/m) x height (1,500m/m), allowing easy transportation and installation

The most competitive pricing in Korea

- Our long-term R&D for two-component liquid dispenser equipment has enabled us to lower the price range by up to 30-20% than the existing equipment.

Board with a microprocessor installed in a two-component liquid dispenser control for the first time in Korea

- Simplify the control function and achieve cost reduction compared to the existing PLC

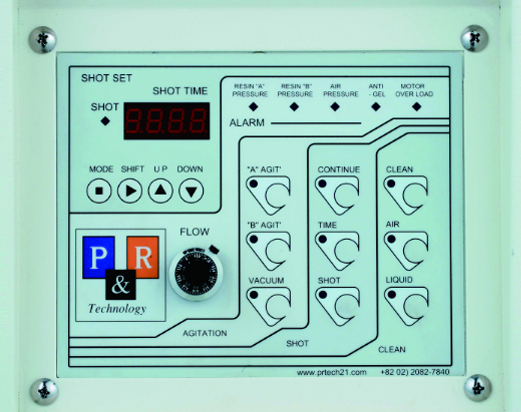

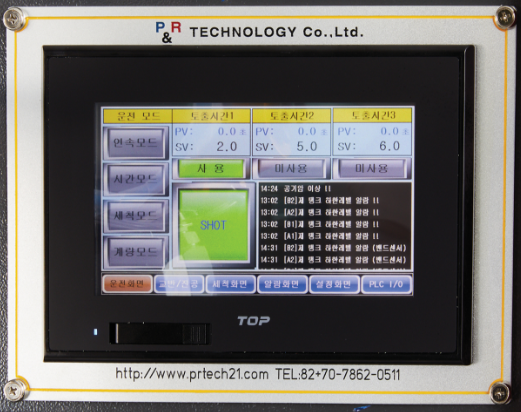

Control Panel Part

Flow Control Dial

Dispensing Timer

Warning Function (Status)

- Main/curing agent abnormality indicator lamp: A pressure switch is attached to the pipes, and the indicator lamp turns on when overloaded to prevent the hose line from bursting or changing due to overload of the pump and hose lines

- Installed anti-gel timer automatically discharges the mixture inside the mixer if no operation is performed beyond the pot-life of the liquid.

Cleaning Mode

All cleaning operations, except for the air-in to the clean tank, are operated from the wash mode button on the control panel. The two-phase cleaning methods using the liquid and air provides spotless cleaning. The proper sealing material minimizes the malfunction caused by the cleaning agent, and the level gage installed on the cleaning tank shows the remaining materials in the cleaning tank.

Micro Processor Type

Touch Panel Type

Static Mixer Part

- Take best mixing effects an increasing the mixer element owing to kinds of material and possible mixer element of material up to 24/36/48 stages.

- Existing dynamic mixers require continuous maintenance and the replacement of sealing elements due to wear as the motor rotates the mixer components. However, with proper washing, this mixer has a near-indefinite lifespan stemming from mixing the ingredients after passing through the pipe.

- Structurally advantageous with the easier replacement of the sealing elements and less maintenance

Static Power Mixer

Power Mixer Type

Block Type