- Home

- Product

- Hot Melt Low Pressure Injection Machine

Product

We provide the best products and services

Hot Melt Low Pressure Injection Machine

Hot Melt Low Pressure Injection Molding System

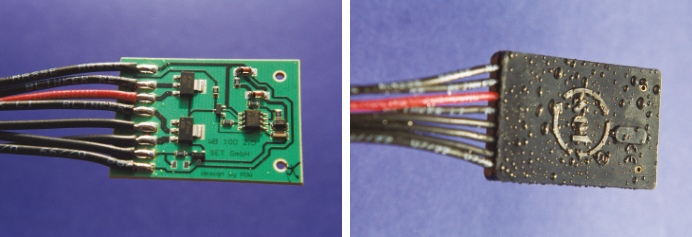

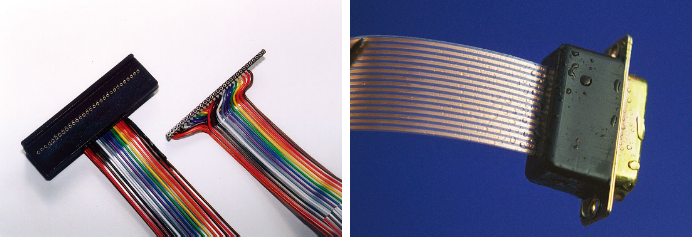

Injection molding equipment using hot melt resin (Macromelt / HENKEL) to replace the existing epoxy/silicone/urethane resin. It is used for the precision molding of the sensors/relays/switches/plugs/connectors/PCBs of automobiles, electric, and electronic components.

Product Benefits

- No damage to parts by the low-temperature/low-pressure injection

- Increased productivity by rapid curing (curing time 10 to 15 seconds) compared to the existing two-component resins

- Environmentally friendly, solvent-free, and non-toxic material is harmless to operators and is flame retardant

- The excellent electrical properties make it usable for an insulator

- Excellent waterproofing performance

- Fast model changeover when changing the mold

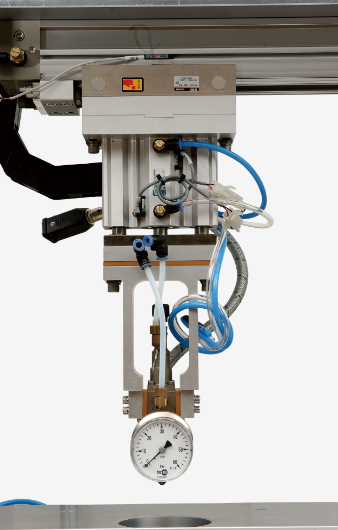

Nozzle

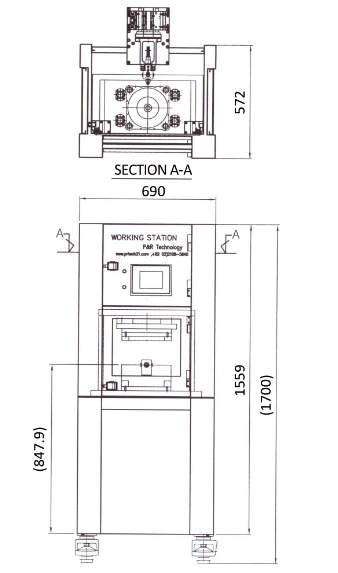

Single Press Type

PCB

Connector

Single Press Type Available for Order

Capable of being connected to the Hot Melt Applicator

Nozzle can be selected in the Vertical or Horizontal type

‘Mold temperature controller’ can be attached as an additional device (optional)

Increase productivity in mass production by reducing the loading and unloading time of products with a Dual Press Type

The operation is easy and simple by using the touch panel in the control part