- Home

- Product

- Two-Component Liquid Meter Mix Dispenser

Product

We provide the best products and services

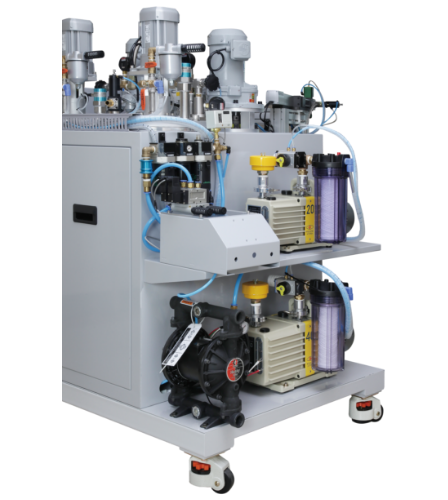

Meter Mix Dispenser Complex PR-2D Ⓡ

The complex PR-2D Type is true to the basic concept of a two-component liquid meter mixing dispenser and is the best equipment for dispensing the epoxy, urethane, silicone, and such. This equipment has added new functions that are differentiated from the existing equipment to meet the diverse needs of customers and maximize productivity.

Comparison to the existing equipment

Existing equipment

Complex PR-2D

When using resins with high viscosity or abrasive fillers

Problem

During the use of the gear pump for transferring the main material/curing agent, the pump wears out quickly, resulting in a loss of gear and shortening the life of the pump.

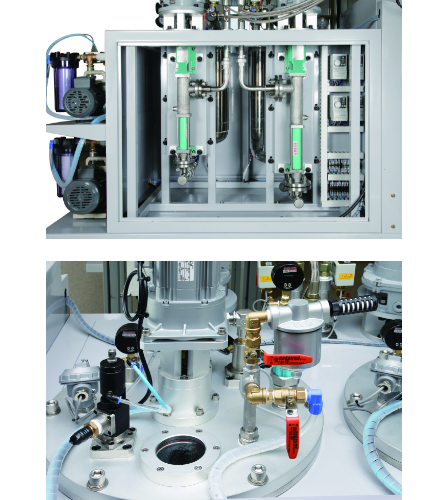

Use of precision piston pumps

Problem

When the equipment is stopped due to the resin filler, resin in the pipe settles and clogs the pipe.

Use of a circulation pump

Problem

The amount of discharge fluctuates wildly, and the hardening failure often occurs when a small amount is discharged.

Use of a precision dispensing mechanism

(For example: when testing with epoxy with a specific gravity of 1.7 and the viscosity of 30,000cps, at a mixing ratio of 100:25)

Dispensing 2gram (±1 ~ 2%)

| 1 | 2 | 3 | 4 | 5 |

| 1.96 gram | 1.97 gram | 1.97 gram | 1.93 gram | 1.95 gram |

When more production is required than the existing equipment

Problem

There is no other way to increase the quantity of equipment than extending the operating hours

- Complex PR-2D can be expanded from 1 unit to up to 4 units

- Each can work independently

- Reduce the purchase price of equipment

During the vacuuming/defoaming process to remove bubbles in the resin bubbles in the tank

Problem

There are differences depending on the manufacturer or the types of resin. However, production loss generally occurs due to the interruption of the discharge operation during vacuum defoaming for 1 hour. The impact is even more significant if the defoaming procedure is performed for a more extended period (2 to 3 hours or more).

Vacuum defoaming can operate concurrently with the dispensing operation without being a stand-alone process

Company E from Italy

We have received the following positive feedback via e-mail.

Company F from Germany

Secured the purchase order from a German company, F, while competing against the German market leader.

Two valves can be operated individually by two operators simultaneously

Back of the equipment

Window installed at the top portion of the tank

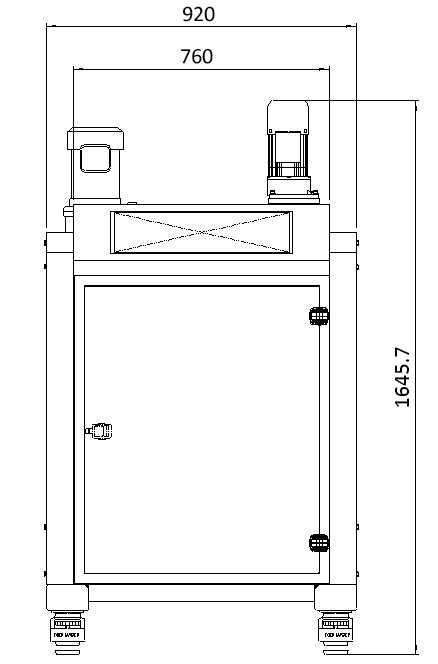

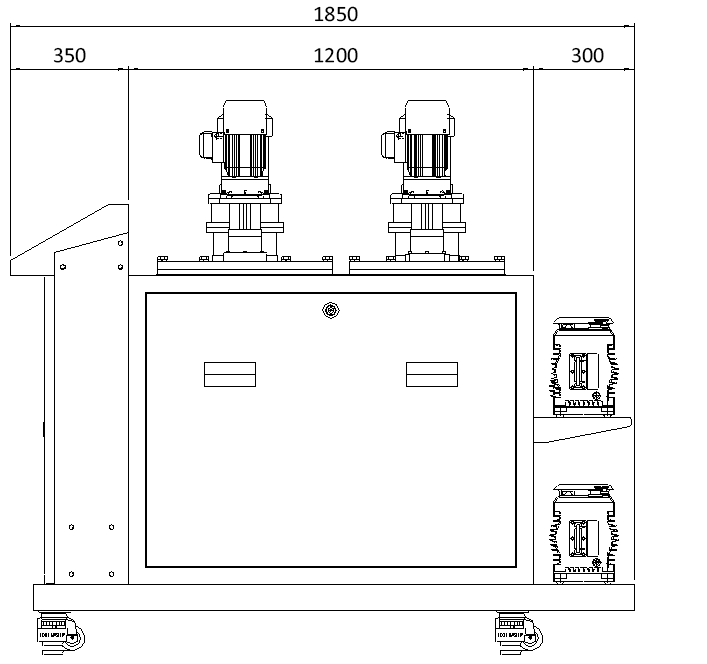

Equipment SIZE (W×D×H)

920 × 1,850 × 1,645 (m/m)